NO-CORRO® VCI corrosion protection

THE RIGHT PRODUCT FOR EVERY APPLICATION

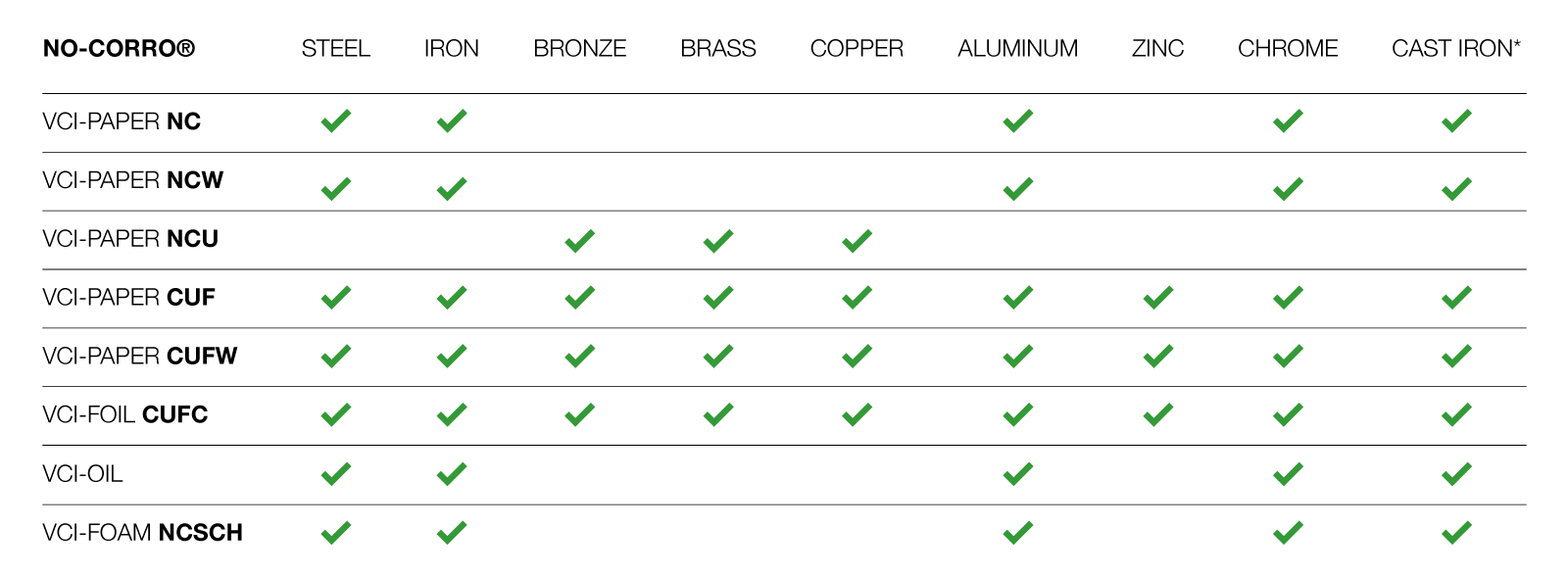

Based on our many years of experience, additionally confirmed by climate chamber and field tests, we would like to show you the possible applications of NO-CORRO® in the following table. In order to be able to offer you the optimal packaging solution, we need additional information from you about e.g. climatic zone, shipping method, storage duration, etc.

WORKING METHOD

The VCI active ingredients anchored in our NO-CORRO® products continuously evaporate and form a protective atmosphere that is deposited on the metal parts. In the case of condensation water formation due to the dew point being undershot, the condensation water is passivated due to the formation of ions from the NO-CORRO® active ingredient. After the condensation has evaporated, the active ingredients remain as a molecular layer on the metal surface. If condensation water forms again, it is passivated again. The lower vapour pressure of NO-CORRO® is approx. 10-² mbar less than the evaporation of the condensation water, so that an amount of the active ingredient of NO-CORRO® always remains on the metal parts.

PROTECTIVE EFFECT

The protective effect sets in after the VCI active ingredients have entered the vapour phase. The duration of protection depends essentially on additional packaging or the movement of air within the warehouse. When using NO-CORRO® products, we recommend an outer barrier layer so that a sufficient VCI atmosphere can build up. When shipping to particularly corrosive climates, a water-vapour-tight barrier is generally recommended. The long-term effect of the corrosion protection of VCI products increases significantly with the water vapour density of the outer barrier layer.

STORAGE

NO-CORRO® products can be stored in a closed PE cover of approx. 100 µm in a cool and dry place at an ambient temperature of a maximum of 25 °C for approx. 12 months without any loss of active ingredient. NO-CORRO® products must be resealed immediately after use so that no loss of active ingredients occurs.

Long-term corrosion protection

In summary, it can be said that with corrosion protection using NO-CORRO® inhibitors, regardless of whether for ferrous or non-ferrous metals, an additional oil or grease layer is not required in most applications.

An additional use of oil is possible, but we recommend our NO-CORRO® VCI OIL to ensure that incompatible corrosion protection additives do not negatively affect the protective effect.